Biocon Biologics Pharma Jobs For Graduates: Walk-In-Interview!

Biocon Biologics is offering an exclusive walk-in interview opportunity for pharmaceutical candidates. Join us to explore exciting career prospects and contribute to innovative biopharmaceutical advancements. Don’t miss this chance to be part of our dynamic team.

#WalkinHyderabad: Are you ready to take your career to new heights?

#BioconBiologics is on the lookout for talented individuals with a passion for innovation and a drive for excellence.

Essential Qualification : MSc / BSc / M.Pharma / B.Pharma / B.E / B.Tech / M.E / M.Tech / Diploma.

Location: Bangalore

Company: Biocon Biologics

Biocon Biologics Hiring Pharma Graduates. The required Skill Set are as follows : 2 – 15 years of experience in the below-mentioned skill set

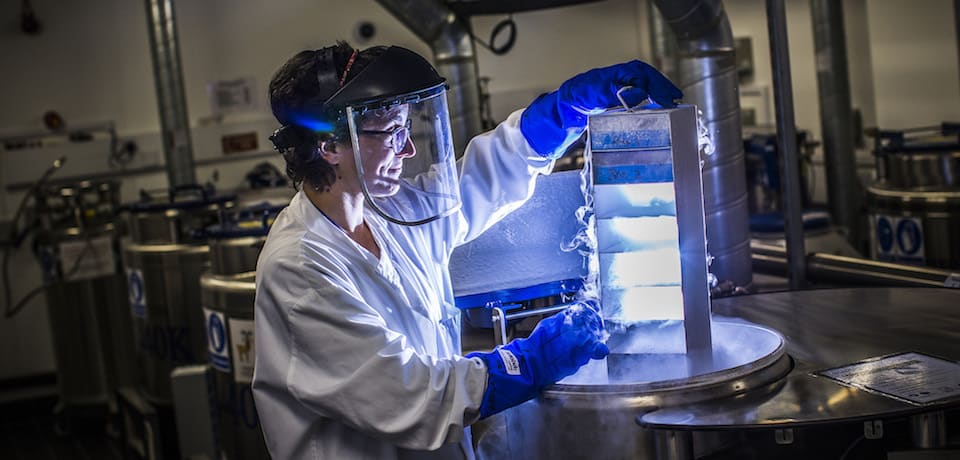

- Aseptic Manufacturing (Vial Washing, Filling, PFS & Sealing)

- Medical Device & Packing (Labelling, Cartooning, Pick & Place Robotic Machines Handling & Track & Trace)

- DP & DS Engineering & Maintenance (Instrumentation, Maintenance)

- Upstream Manufacturing (Mammalian & Microbial)

- Downstream Manufacturing (Mammalian & Microbial)

Qualification – MSc / BSc / M.Pharma / B.Pharma / B.E / B.Tech / M.E / M.Tech / Diploma

Venue of Walk-in-Interview:

Hotel Avasa,

Survey No. 64, 15, 24, 25 and 26

Hitech City Rd, HUDA Techno Enclave

Sector 1 , Hyderabad, Telangana, 500081.

Date and Time of Interview: Sunday, 24 September 2023, 8.30am to 12.00pm.

Note:

- Candidates who have attended the interview in Biocon Biologics in last six months are not eligible.

- Please carry your updates resume, highest qualification certificate, latest increment letter and pay slips for past three months.

- If you’re passionate about making a difference in the biopharmaceutical industry and possess the skills we’re looking for, don’t miss this chance! Come meet our team and discover how you can contribute to our mission of improving global healthcare.

Biocon Biologics Pharma Jobs For Graduates. The possible interview Q & A to help you with :

1. Question: Can you describe your experience with aseptic manufacturing processes, including vial washing, filling, PFS (Pre-filled Syringes), and sealing?

Answer: I have over 10 years of experience in aseptic manufacturing processes. During my tenure at my previous company, I was responsible for overseeing vial washing, filling, PFS assembly, and sealing operations. I ensured that all processes adhered to strict quality and regulatory standards, and I actively participated in troubleshooting and optimizing these processes for efficiency and safety.

2. Question: How familiar are you with medical device packaging, including labeling, cartooning, and handling pick & place robotic machines?

Answer: I have 5 years of experience working with medical device packaging. This included setting up and managing labeling machines, cartooning equipment, and pick & place robotic systems. I was responsible for ensuring that all medical devices were correctly labeled, packaged, and ready for distribution. My experience also involved overseeing track and trace systems to ensure product traceability and compliance with regulatory requirements.

3. Question: Can you discuss your background in DP (Drug Product) and DS (Drug Substance) engineering and maintenance, particularly in terms of instrumentation and maintenance activities?

Answer: Over my 12-year career, I have been actively involved in DP and DS engineering and maintenance. I have extensive experience with instrumentation calibration and troubleshooting to maintain the accuracy and reliability of critical equipment. Additionally, I’ve led maintenance teams in conducting preventive and corrective maintenance activities, ensuring minimal downtime and optimal equipment performance in drug substance and drug product manufacturing processes.

4. Question: Could you elaborate on your experience in upstream manufacturing, specifically in both mammalian and microbial processes?

Answer: I have 8 years of experience in upstream manufacturing, covering both mammalian and microbial processes. In my previous roles, I managed bioreactor operations, cell culture processes, and fermentation activities for the production of biopharmaceuticals. I ensured that all processes were well-controlled, optimized, and met product specifications while adhering to GMP (Good Manufacturing Practices) guidelines.

5. Question: Can you provide details about your involvement in downstream manufacturing, particularly in mammalian and microbial processes?

Answer: In my 15 years of experience, I’ve been deeply involved in downstream manufacturing for both mammalian and microbial processes. This included purification, filtration, chromatography, and formulation activities to transform raw materials into finished drug products. I’ve overseen process development, scale-up, and tech transfer to ensure the efficient and cost-effective production of high-quality pharmaceuticals. My experience also includes implementing process improvements to enhance yield, purity, and product consistency.