Propylene oxide (PO) is a high value-added chemical intermediate. In comparison to conventional routes to produce PO, direct epoxidation of propylene with H2 and O2 is a green, efficient, and sustainable approach. However, the currently used Au catalyst in this approach is high-cost and with limited reserves. Therefore, it is urgent to develop highly-active non-noble catalysts for propylene epoxidation.

A research team led by Prof. Chen Xinqing from the Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences has proposed non-noble nickel catalysts supported on titanium silicate-1 (TS-1) zeolite, which exhibits excellent catalytic performance in the gas-phase epoxidation of propylene.

The research results were published in ACS Catalysis on July 27.

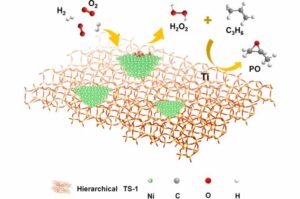

The researchers synthesized a series of non-noble Ni/TS-1 catalysts by the deposition precipitation method. They found that the strong metal-support interaction between Ni nanoparticles and TS-1 was the reason for their good catalytic performance in the gas-phase epoxidation of propylene.

The prepared 2% Ni/TS-1 catalyst reached a high PO selectivity of 76.8% and PO production rate of 151.9 g PO/(h·Kgcat). Its long-term stability at 200 °C exceeded 20 hours.

Moreover, the researchers investigated various characterizations of the catalyst to understand the reaction mechanism with the help of

in-situ technologies. The results showed that metallic Ni promoted the reaction between hydrogen and oxygen for the in-situ synthesis of H2O2 and then oxidized propylene to PO. Theoretical calculations revealed that the passivation layer on the Ni surface enabled the production of H2O2.Non-noble nickel catalysts Looking for latest chemistry and Pharma job openings, follow Rasayanika Facebook and Telegram and subscribe to our youtube channel for the latest updates on chemistry and Pharma job.