RUDN University develops green catalyst for pharma and industrial chemistry

Nanocatalysts that contain palladium – a costly component that is not sustainably generated, is used in a lot of manufacturing facilities (e.g. plastic manufacturers, pharma companies, etc). A method, to minimize palladium usage and also to make its manufacture much more environmentally friend, was discovered by a chemist from RUDN University. The catalyst is based on a substance that originates from plant waste. Manufacturers could reduce palladium usage to 50% using this development. Furthermore, the new catalysts can be recycled numerous times without any decline in the effectiveness. The outcomes of the research were released in the journal Molecular Catalysis.

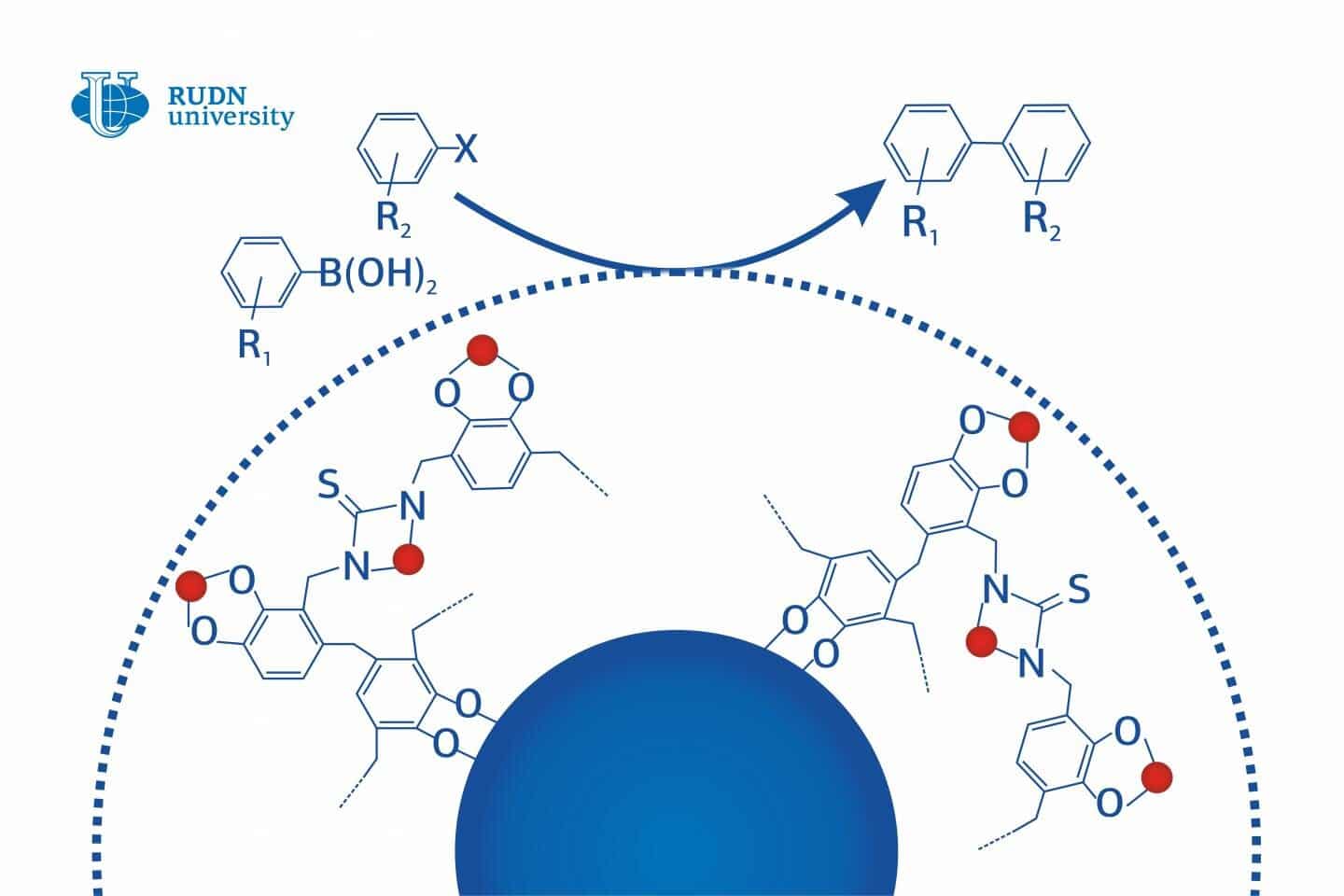

A type of reaction that entails incorporating carbon atoms from different organic molecules is called cross-coupling reaction, which is the most extensively spread out in industrial chemistry. Cross-coupling reactions are utilized to synthesize plastics, medicines, and various other compounds, and account for 17% of all reactions in jus medical chemistry. The primary part of cross-coupling is palladium nanoparticles, which is among the rarest elements on Earth, making it a very expensive catalyst. Furthermore, it is primarily produced at mining facilities that posture a considerable risk to the atmosphere. The chemist

claimed that all these problems can be solved using this novel technique.Due to the fact that the particles of palladium-containing catalysts have a tendency to bind with each other, the usage of palladium in cross-coupling reactions raises. There are 2 methods to prevent this:

- To weaken the reaction between their surfaces when they come in contact, the chemical properties of the particles can be modified.

- The metal could be kept in place physically with a grid or a structure. The researcher selected the second method and locked metal fragments in their respective places utilizing a multilayer covering with a magnetic core.

The new nanocatalyst’s core includes iron oxide having high magnetic properties, the covering is constructed from a polymer, based on catechol – a material that is present in plant cell walls, produced from plant wastes. There is no catalytic activity in both these layers as it is secondary. Palladium nanoparticles that are fused right into the 2nd layer are the source of the catalytic properties of the compound. The particles are fixed by the polymer in position as well as stops it from binding.

Two times as little palladium as the old one: 1.5% of the overall nanoparticle weight in contrast to 3-6% is required in this newly developed catalyst. Additionally, the center of the nanocomposite material can be cleaned and used again after a couple of production cycles. This method is great for the environment and likewise, it is financially practical, as it will certainly make the production of medicinal drugs, plastics, and various other items less expensive.

Rafael Luque, Ph.D., RUDN University said that as of now, eco-friendly green catalysts are the interest of many chemists. The nanocatalysts effectively work in cross-coupling reactions and it contains a product of plant waste recycling. As a result, they capable to minimize palladium usage and also make the manufacturing process less expensive, and they are likewise advantageous for the ecosystem. Additionally, they succeeded to exhibit the universal characteristic of polymers based upon plant catechols. When dealing with various other metals or with catalysts of other organic reactions, the same approach can be utilized.

RUDN University develops green catalyst for pharma and industrial chemistry

Author: Sruthi S