New Portable “Biofactories” To Preserve Medicines and Chemicals

A new way to produce and preserve medicines and chemicals has been developed by a team of chemical engineers. They developed portable “biofactories” embedded in water-based gels known as hydrogels for preserving the chemicals and medicines. In remote villages or on military missions, this approach could help the people as in such places there is the absence of pharmacies and the access to critical medicines and other small-molecule compounds are hard.

The research team was led by Hal Alper, a professor of chemical engineering at the University of Texas, and an assistant professor of chemistry at the University of Washington, also a faculty member in the UW Molecular Engineering & Sciences Institute, Alshakim Nelson. The journal Nature Communications published their paper.

Nelson said, “In the future, for the production of on-demand small-molecule and peptide products, we expect these developments to afford new technologies. In isolated or remote areas where resources and space are limited, this technology will be applicable.”

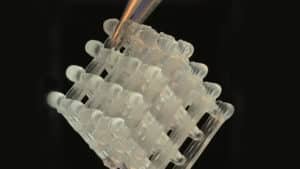

The system allows for portability and optimized production has it effectively embeds the cells engineered to overproduce a product, the microbial biofactories, into the solid scaffold of a hydrogel. Similar to the systems used for

processes such as fuel and pharmaceutical production, with the in-the-moment production of high-value chemical feedstocks, this is the first hydrogel-based system to organize both individual microbes and consortia. In just a couple of hours to a couple of days, products can be produced.Alper said, “Many of the pharmaceuticals, nutraceuticals, fuels, and chemicals we use rely on traditional fermentation technology. The ability to provide a means for both on-demand and repeated-use production of chemicals and antibiotics from both mono- and co-cultures is provided by our technology, addressing this strong limitation in the fields of synthetic biology and bioprocessing.

In this work, the hydrogel can be manually extruded or 3D printed. Upon exposure to UV light, the gel material along with the cells inside which flows like a liquid can harden. This results in a polymer network which has too small space for cells to leak out and has large space for molecules and proteins to move through it.

The hydrogel system can effectively preserve the fermentation capacity of the biofactories until needed in the future when the system is subjected to freeze-drying. By simply adding sugar, water, and other basic nutrients, the hydrogel can be revived and just effectively as before the preservation process, the cells could resume production.

The ability to combine many different organisms called consortia, together in a way that outperforms traditional, large-scale bioreactors is one of the novel applications enabled by this platform.

Keeping different types of cells separated while they grow and preventing one from taking over and killing off the others, this platform has the added benefit of multitasking. Similarly, by keeping the growth of multiple cell types balanced, the team could control the dynamics of the system by testing a range of temperatures.

The team showed repeated and continuous use of the system with yeast cells, over an entire year without any decrease in yields, which indicated the process’ sustainability over time.

There are fixed shelf life and specific storage conditions required for medicines such as antibiotics. In remote places that don’t have access to refrigeration to store medications, the hydrogel system is especially useful as it is a portable biofactory that can synthesize these molecules. When there is no access to a pharmacy or a store, like during a military mission or a mission to Mars, this system would be a compact and small way to access and maintain several medications and other essential chemicals. The possibilities are promising even though we are not quite there yet.

Alper said, ” To a wide range of cell types and products, this technology can be applied. To produce diverse products that are needed for a specific scenario, scientists and engineers are able to plug and play with different consortia of cells. This is the part that makes this technology so exciting.”

The paper’s co-lead authors are Shuo-Fu Yuan, University of Texas graduate student and Trevor Johnston, UW graduate student. Patrick Smith, a UW graduate student, Abhijit Saha, former UW postdoctoral researcher, Xiunan Yi and James Wagner at the University of Texas are the co-authors of the paper. The Royalty Research Fund, the University of Washington and the Camille and Henry Dreyfus Foundation funded this research.

Edit: Preserving Chemicals in Portable Biofactories, Preserving Chemicals in Portable Biofactories