Renewable Plant Biomass-based Polymers Created by Chemists

St. Petersburg University researchers have used biomass to develop polymers at their Laboratory of Cluster Analysis. Their specialty is that these polymers can also be easily recycled.

Polymers are an indispensable part of our lives with their presence in paints, plastics, lacquer coating, films, fibers, etc. They are used by us both in industries and our daily lives. However, these polymers’ problem is that the goods made from them are disposed of after one single use. Even during recycling, the chemicals that are released may cause serious environmental damage. Nevertheless, some polymers can be recycled multiple times, leading to a process called secondary recycling. But the products generated from primary raw materials are far better in quality than those obtained from secondary raw materials.

To tackle the above problems, renewable plant biomass-based polymers were developed by chemists. These have biomass compounds as their base. For the chemical industry’s future, biomass seems to be the most reliable and renewable source of raw materials. Terpinols derived

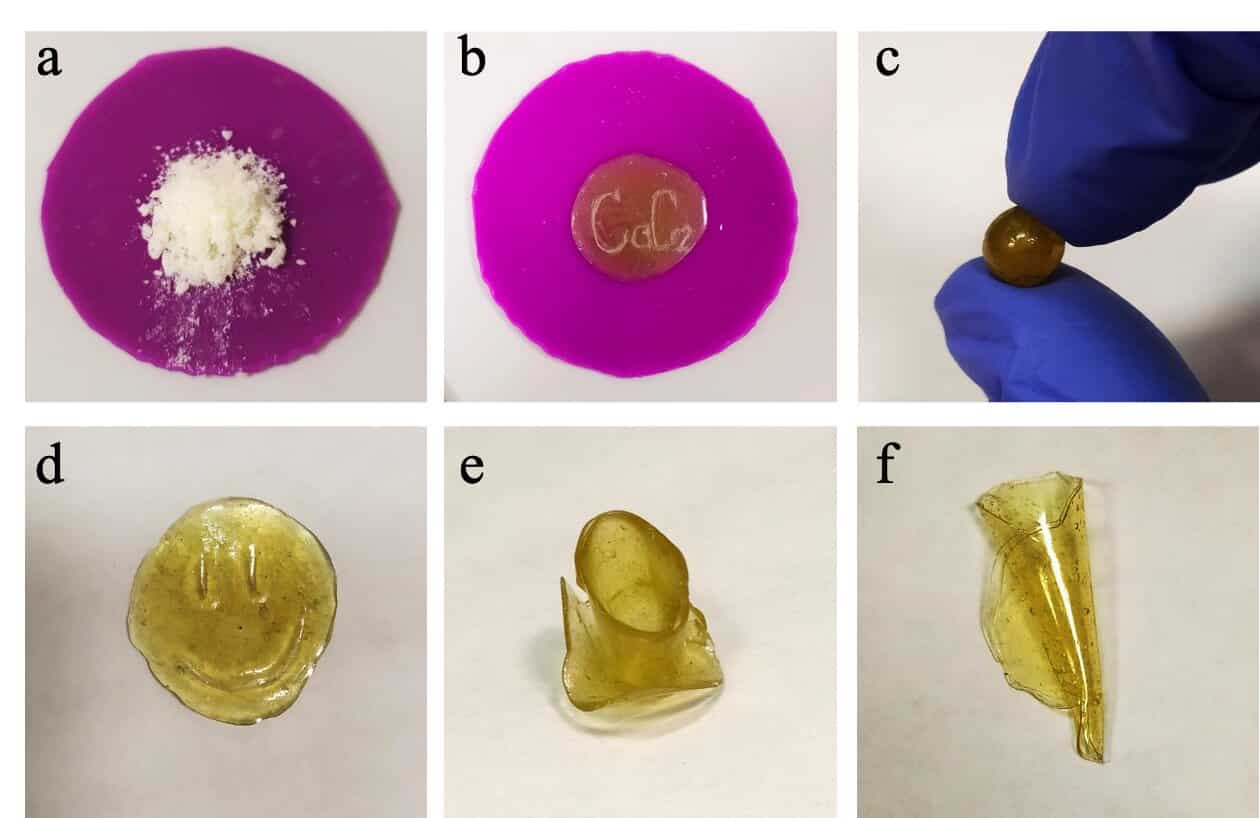

from naturally synthesized alcohol are an excellent example. They include Mint’s essential oil product menthol and white fir tree-extracted borneol, derived from the tree’s essential oils.Secondary as well as primary recycling can be performed for these synthesized renewable plant biomass-based polymers. The polymer product can be transformed into its primary compounds upon secondary recycling, followed by further polymerization. These processes only require moderate temperatures.

The article’s first author and a St. Petersburg University scientist at the Laboratory of Cluster Analysis, Svetlana Metlyaeva, explained the above process and clarified that it is based on the polymer. Natural alcohols or their derivatives can be obtained from the non-oxygenated recycling of these polymers. The compounds derived can then be converted back into the same alcohols. She also said that at 120°C, this type of polymer could be melted and shaped as desired. It becomes hard during the cooling process. It was interesting to note that multiple melting processes made no difference to the polymer’s properties even after the above cycle was repeated 7 times by the chemists.

The university’s researchers look forward to continuing research on these polymers in their Research Park. They have spoken about their aim to study Renewable Plant biomass-based polymers such as strength, elasticity, resilience, and other mechanical properties. This forms a step towards figuring out the applications of their research in the chemical industry.

Svetlana Metlyaeva spoke about the varying properties of the polymer, which they have only managed to synthesize. The prospects of using them will come into the picture once they figure out the modification processes and their resulting materials.