Process Engineering Jobs at Sansera | Chemistry Candidates Apply

Are you looking for Process Engineering Jobs in a leading aerospace manufacturing company? Sansera Careers is hiring skilled professionals for Special Process – Process Engineering roles in Bangalore. This opportunity is ideal for candidates seeking Chemical Engineering Jobs with hands-on exposure to aerospace standards, surface treatment processes, and Nadcap audit management.

About Sansera Engineering:

Sansera Engineering is a leading manufacturing company serving the aerospace, automotive, and industrial sectors. Known for precision engineering and advanced manufacturing capabilities, Sansera Careers offers excellent opportunities in Process Engineering Jobs and Chemical Engineering Jobs, with strong exposure to aerospace standards, Nadcap compliance, and a continuous improvement culture.

- Job Title: Special Process- Process Engineering

- Location: Bangalore, Jigani

- Job Type: Full-time

Job Description:

As a Special Process- Process Engineering, you will be responsible for developing and implementing special processes to improve manufacturing efficiency, reduce waste, and ensure compliance with industry standards. You will work closely with cross-functional teams to identify process bottlenecks and develop solutions to enhance overall operational performance.

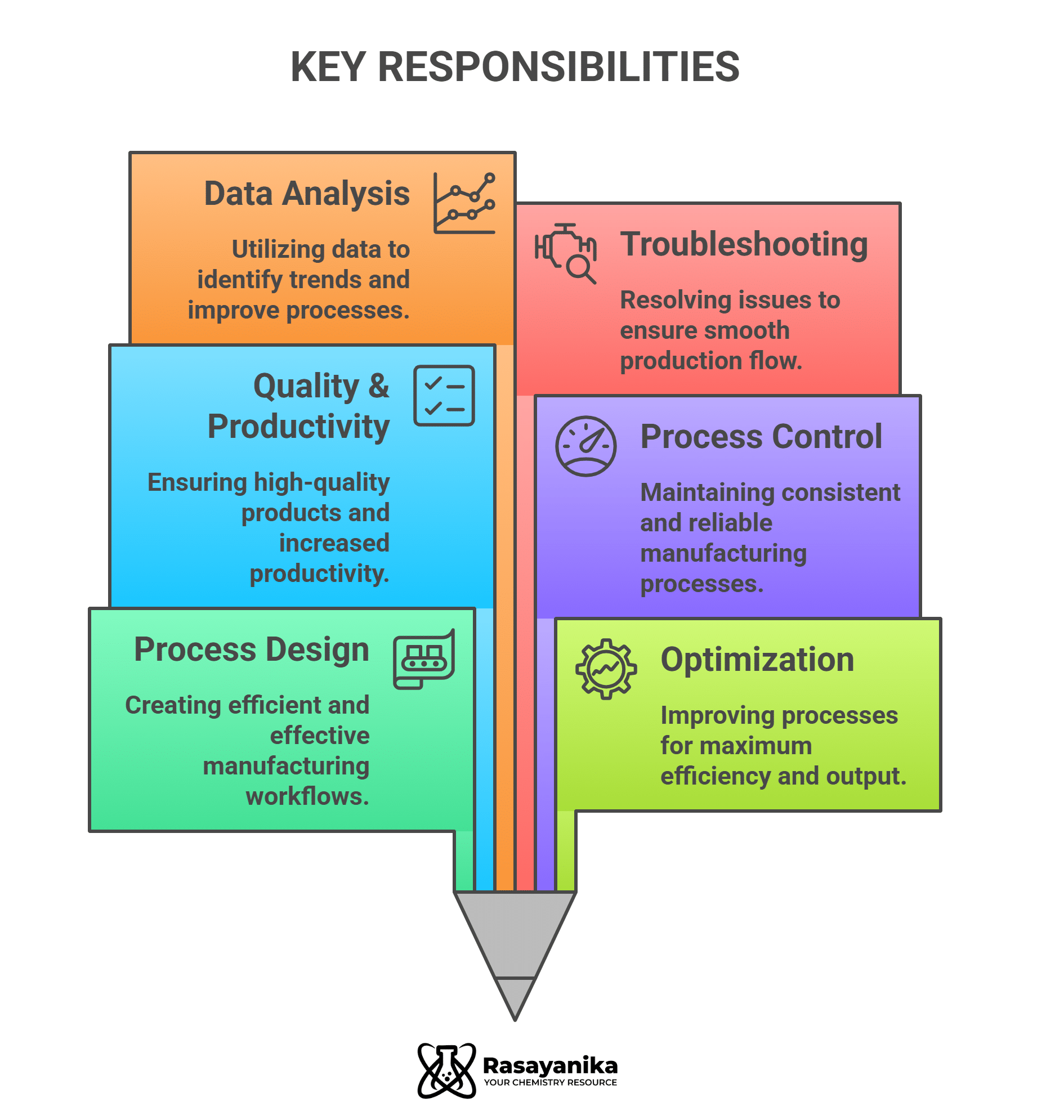

Key Responsibilities:

- Design and implement special processes to improve manufacturing productivity and product quality.

- Conduct thorough analysis of current manufacturing processes, identify areas of improvement, and develop strategies to optimize performance.

- Collaborate with engineering and quality control teams to ensure that special processes are consistent with industry standards and regulatory requirements.

- Implement and maintain process control measures to monitor and enhance process performance.

- Provide technical support to production teams and troubleshoot any process-related issues that may arise.

- Utilize statistical tools and software to analyze data and identify trends that may impact manufacturing processes.

- Develop and maintain process documentation, including standard operating procedures and work instructions.

- Participate in continuous improvement initiatives and drive innovation in special process engineering.

- Nadcap Audit management.

- Should have hands-on experience in Surface treatments such as Anodizing, Painting, Electroplating, and electroless plating.

- Should be proficient in interpreting the Aerospace standards and specifications of all the Primes and OEM’s.

Qualifications:

- Bachelor’s degree in Chemical Engineering or Mechanical related field.

- Proven experience in process engineering, preferably in a manufacturing environment.

- Strong analytical and problem-solving skills.

- Proficiency in using statistical and data analysis tools.

- Excellent communication and interpersonal skills.

- Ability to work effectively in a team-based environment.

- Knowledge of industry standards and best practices in process engineering.

- Nadcap and AS9100 audit management.

Department: Special Process

Open Positions: 2

Skills Required: Manufacturing Engineering, Aerospace, Process Engineering, Surface Treatment, Nadcap

- Location: Bangalore, Karnataka, India

- Education/Qualification: BE Chemical/ BE Mechanical

- Years of Exp: 2 to 5 years

- Designation: Engineer

Key Roles and Responsibilities:

1. Process Development: You will be responsible for conceptualizing, designing, and developing special processes to improve operational efficiency and productivity. This may involve conducting research, performing feasibility studies, and collaborating with other engineers and stakeholders to identify and implement new processes.

2. Process Implementation: Once a new process has been developed, it will be your responsibility to ensure the smooth and successful implementation of these processes within the organization. You will work closely with various teams to train personnel, troubleshoot any issues, and monitor the performance of the new processes.

3. Process Maintenance: As a Special Process- Process Engineer, you will also be responsible for maintaining and optimizing existing processes to ensure continuous improvement. This may involve conducting regular audits, identifying areas for improvement, and implementing changes to enhance the effectiveness of the processes.

4. Compliance and Regulatory Standards: You will need to ensure that all special processes within the organization comply with industry standards, Nadcap, and Other customer regulations and safety protocols. This may involve working closely with regulatory bodies and quality assurance teams to ensure that all processes meet the required standards.

5. Project Management: In some cases, you may be responsible for managing specific projects related to process engineering. This may involve coordinating with multiple teams, setting project timelines, and ensuring that all deliverables are met within the designated timeframe.

6. Continuous Improvement: As a process engineer, you will be expected to proactively seek out opportunities for continuous improvement. This may involve analyzing data, gathering feedback from employees, and implementing new technologies or methodologies to further enhance processes.

7. Communication and Collaboration: Effective communication and collaboration with various stakeholders, including management, cross-functional teams, and external partners, will be crucial in your role as a Special Process- Process Engineer.