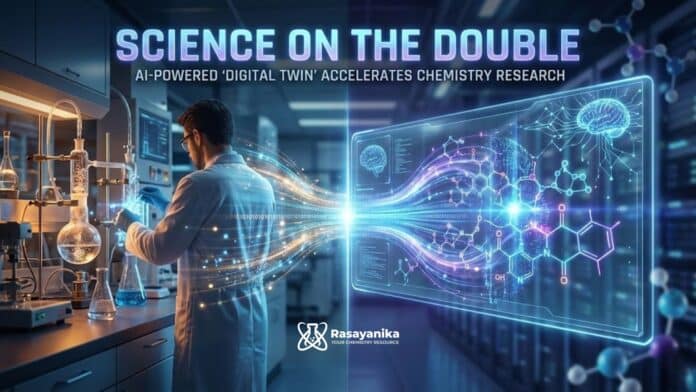

AI Digital Twin Speeds Up Chemistry Research

Scientists at the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) have created a new AI-powered platform that could dramatically speed up chemistry research. The system, called Digital Twin for Chemical Science (DTCS), can shorten research timelines from months to just minutes.

Understanding complex chemical experiments usually takes weeks or even months. Researchers collect large amounts of data, then analyze it later using computer models. Only after that can they test their ideas again. This back-and-forth process is slow.

DTCS changes that. It allows scientists to watch chemical reactions, adjust their

experiments, and test their ideas — all during a single experiment. Instead of waiting months to see if their theory matches the data, researchers can get answers in real time.

“A common challenge is that we have powerful tools to collect data, but interpreting it is much harder,” said Jin Qian, a computational chemist at Berkeley Lab who designed DTCS. She explained that scientists usually analyze data offline through simulations, which can take months before theory and experiment agree. DTCS helps remove this delay.

The platform is a major step toward autonomous chemical research, where AI helps guide experiments and speed up the discovery of new materials and chemical processes.

DTCS works by creating a “digital twin,” or virtual copy, of a real experiment. Digital twins use live data from physical systems to model what is happening and predict what will happen next. While digital twins have long been used in fields like aerospace, healthcare, and manufacturing, DTCS is one of the first built specifically for chemical research.

The system creates a digital replica of a technique called ambient-pressure X-ray photoelectron spectroscopy (APXPS), used at Berkeley Lab’s Advanced Light Source (ALS). APXPS helps scientists study chemical reactions on surfaces, such as those inside batteries, fuel cells, and manufacturing systems. It identifies chemical compounds by their unique “fingerprints” as they form on surfaces under real-world conditions.

In traditional APXPS experiments, scientists cannot easily interpret results in real time. DTCS solves this by comparing live experimental data with computer simulations. It can show how reactions change over time, measure the amount of each chemical species, and even estimate how likely certain molecules are to be near each other. This greatly improves real-time understanding.

To test DTCS, researchers studied a silver and water system important for batteries, catalysis, and corrosion prevention. The platform’s predictions matched previous experiments and theories. It was able to predict when and where oxygen-containing species would appear on the silver surface within minutes.

DTCS operates through two connected processes: a “forward loop,” which matches simulations with experiments, and an “inverse loop,” which uses experimental data to determine the underlying chemical mechanisms.

The research team is now developing DTCS 2.0. They plan to expand it for wider use and train it with more data. They are also building digital twins for other techniques, such as Raman and infrared spectroscopy.

The work was supported by the DOE Office of Science and used computing resources at the National Energy Research Scientific Computing Center (NERSC). Both NERSC and the Advanced Light Source are DOE Office of Science user facilities at Berkeley Lab.

Researchers expect DTCS to be available to other institutions in the next few years, potentially changing how chemistry research is done around the world.