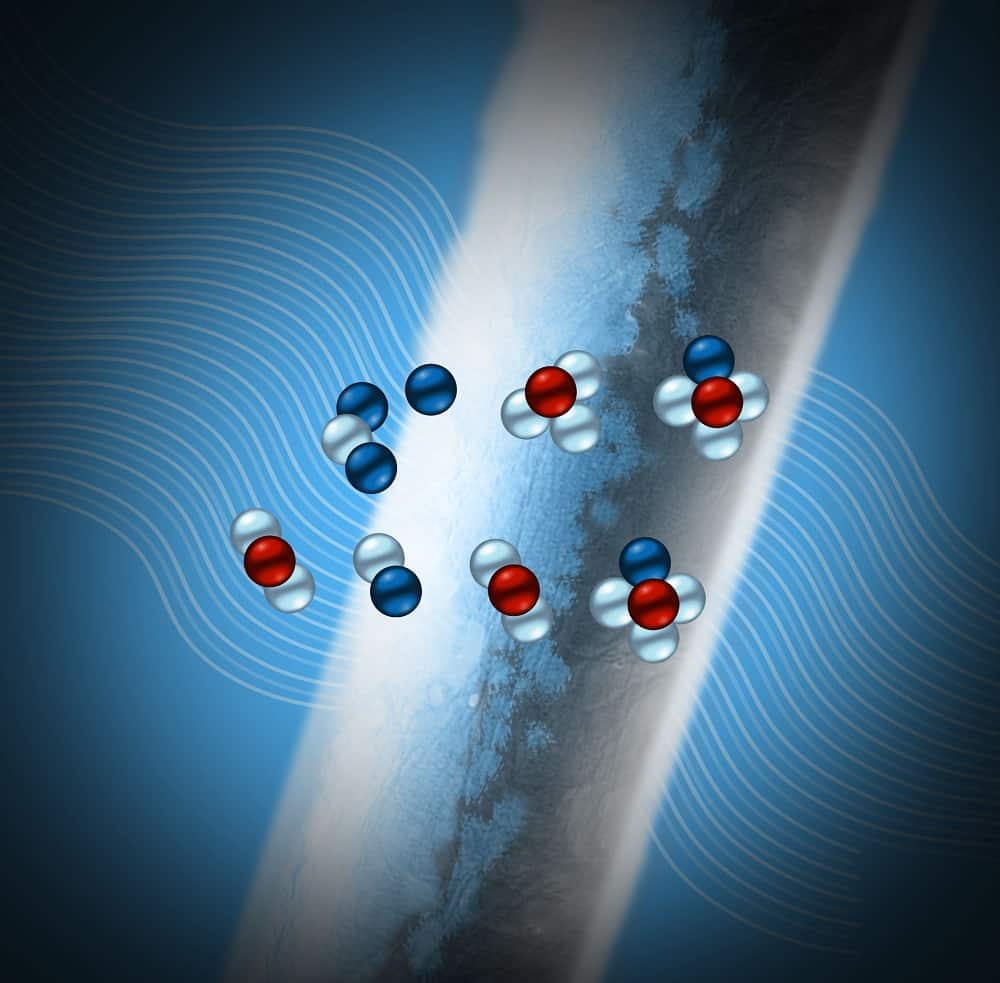

From fragrances and meals flavourings to the construction blocks of pharmaceutical medicine, positive chemical compounds – complicated chemical compounds produced in small amounts to a top level of purity – play a significant position in our day by day lives

However generating those chemical compounds can come at a price, each in financial phrases and the massive quantity of waste generated.

A brand new generation referred to as HydRegen is being evolved via Professor Kylie Vincent and her workforce within the Division of Chemistry on the College of Oxford that guarantees to make the manufacturing of good chemical compounds ‘less expensive, quicker, more secure and cleaner’.

The undertaking used to be just lately awarded an Innovate UK/EPSRC grant value £2.nine million and used to be the total winner of the Royal Society of Chemistry’s Rising Generation festival in 2013.

Dr Holly Reeve, co-investigator and supervisor of the HydRegen venture – which takes its identify from using hydrogen to regenerate a key molecule concerned within the procedure – informed Science Weblog about this award-winning generation.

In a nutshell, what’s HydRegen?

‘The HydRegen generation has the prospective to make the manufacturing of good chemical compounds equivalent to prescription drugs, flavours and fragrances

less expensive, quicker, cleaner and more secure. Chemists increasingly more flip to nature to seek out artful tactics of creating complicated chemical compounds the use of enzymes remoted from the cells of micro organism and different organisms. The HydRegen generation gives an absolutely new method of harnessing the implausible selectivity of those enzymes and can permit enzyme pathways to be carried out into present chemical synthesis methods a lot more simply.’What are probably the most issues of production nice chemical compounds at the moment?

‘Most of the conventional strategies for making high quality chemical compounds be afflicted by a loss of selectivity and generate massive amounts of waste. Those issues imply that pricey purification methods are in most cases required to procure the specified chemical with the extent of purity required through the nice chemical compounds industries.

‘One means for expanding the selectivity and reducing the waste related to a chemical processes is the use of a catalyst which now not most effective hurries up a response however, if designed as it should be, lets in era of best the specified product. In business, steel catalysts are frequently used; on the other hand, those metals have a tendency to be very pricey, extremely poisonous and are in finite provide. Tuning the selectivity of those steel catalysts continues to be a substantial problem for this space of analysis.